Greenhouse second cover (Energy Screen)

Greenhouse second cover

Shimi Plastic has produced a new generation of greenhouse films that are used as an internal sieve and second cover plastic film in the greenhouse.

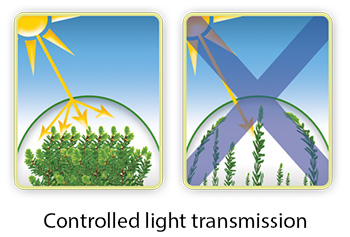

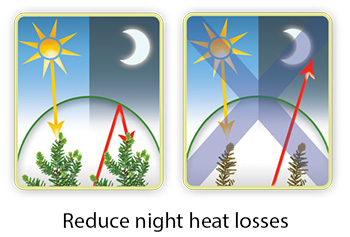

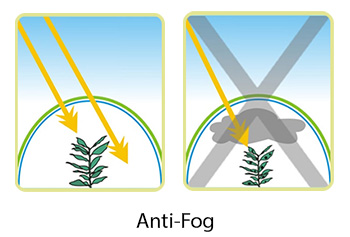

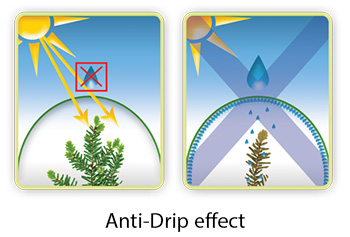

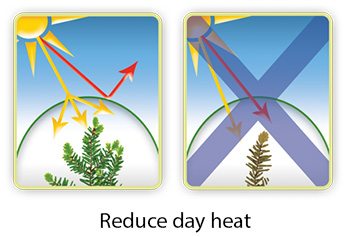

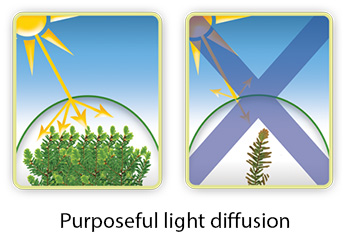

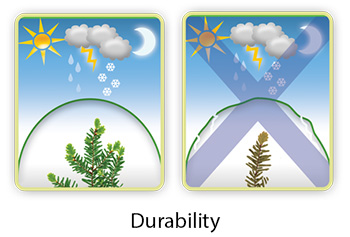

These films limit the night-time temperature drops by absorbing infrared radiations; therefore, reducing fuel and energy costs. These films have high strength, excellent transparency, and Anti-vapor properties.

Due to the need for some greenhouses to use a secondary cover other than their main cover in the greenhouse, We have produced the Energy Screen Film for the second greenhouse cover. This type of plastic film, due to its specific installation method, which is usually 1 to 2 meters below the original greenhouse film, acts as an insulator, especially in colder times of the year. Thus, it keeps the greenhouse warm and prevents energy loss.

Shimi Plastic Yazd company improves the performance of these films by utilizing the best raw materials and additives in the production process. These films create an optimum environment for producing higher quality crops by controlling the plant growth in the greenhouse. The plastic films for the second greenhouse cover produced by the company are lightweight, elastic, and easy to install and protect the greenhouse from harmful UV radiation.

| Specification | Second cover film |

|---|---|

| Film usage | Second cover |

| Manufacturing technology | 3-layer |

| Anti-fog | yes |

| IR | yes |

| Anti-UV | yes |

| Dimension | As per customer’s request |

Specifications of Shimi Plastic’s second greenhouse cover

Some other uses of plastic films for the second greenhouse films