Specifications of plastic films

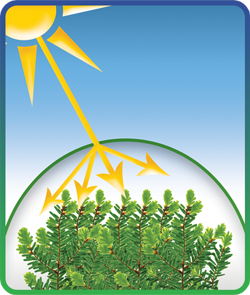

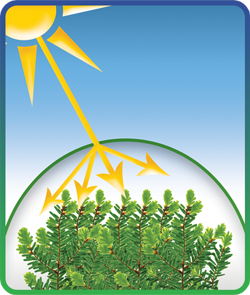

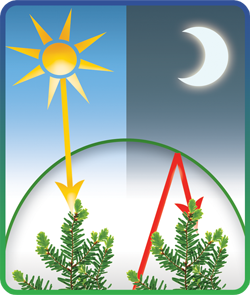

Direct sunlight causes parts of the plant that are exposed to burn, while insufficient light causes the plants to wither. Additives that scatter direct sunlight, create more homogeneous lights in all areas of the greenhouse. This increases the emission of light to reach plants, reduces the plant burning rate and increases light transmission to reach the lower leaves. This feature is especially important for broadleaf plants. Research shows that the proper diffusion and distribution of light in the greenhouse, reduces the spread of fungal spam and the proliferation of pests.

Purposeful light diffusion

Some farmers prefer to change their greenhouse plastics for a little more sunlight attraction during the short winter days. Greenhouse films produced by Simi Plastic Yazd absorb the useful wavelengths from the sun & reflect the unwanted ones. These films promote better plant growth by improving the sunlight impact on flowers and preventing pests from entering the greenhouses to avoid diseases. Efficient, and high light diffusion is one of the key factors in plant growth. Shimi Plastic makes sure to deliver the highest light diffusion efficiency in our films, using our many years of experience in production, high quality equipment, and the best raw materials available in the market.

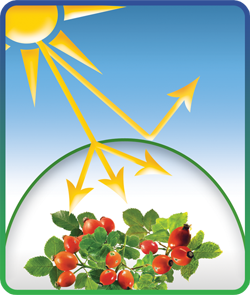

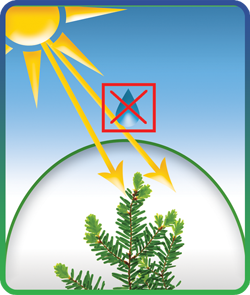

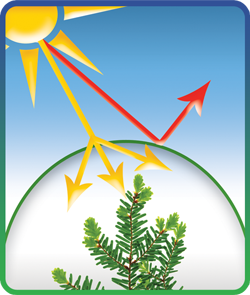

Pest and disease control effect

The human eye is sensitive to UV radiations of 400 to 700 nm, while insects are sensitive to UV radiations of less than 400 nm. Greenhouse films produced by Shimi Plastic with their special combination, absorbs the rays that insects need for guiding and navigating. This action significantly reduces insect’s entrance and activity in the greenhouse, resulting in disappearance of various diseases that they bring in with themselves. A big advantage of these films is helping farmers economically, by reducing the number of pests and insects, therefore lowering the need for using expensive pesticides, and insecticides.

Dust accumulation Prevention

One of the obstacles to efficient light transmission is the accumulation of dust on plastic film in the greenhouse. The collection of dust on the outer surface of the plastic film prevents complete and permanent light transmission and has long-lasting effects on the greenhouse environment and most importantly on the growth of greenhouse plants. The additives in agricultural plastic films of Shimi Plastic Yazd provide maximum rate of light transmission by not allowing dust grains to stick to our films and helping the dust particles get removed easily and effectively from outside of the greenhouse in a minimal amount of time.

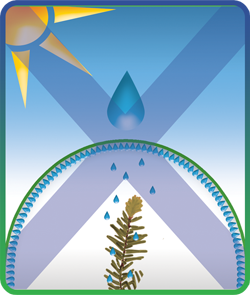

Anti-Fog effects

When the temperature decreases and relative humidity reaches saturation, fog is formed in the greenhouse. The formed fog in the greenhouse harms the plants as the leaves are exposed to a thin, damp layer (up and down); Thereby, the fog blocks the sun radiations for hours after sunrise. These water droplets from the fog act like a lens and burn some parts of the plant. Films produced by Shimi Plastic ensure that the greenhouse is not exposed to fog, and that sunlight is transmitted perfectly by precisely using the right additives in production of our plastic films. Thus, the growth rate of the cultivated crop increases and the time for crop preparation is reduced.

Anti-Drip effect

Due to difference in temperature between inside and outside of the greenhouse, especially at night, humidity and small water droplets in the greenhouse can be created, which can have negative effects on the plant such as disease in cadence due to drop leakage, reducing 15 to 30 percent of the light transmission into the greenhouse, as well as the quality and growth rate of the crop. To solve this problem, Shimi Plastic adds special additives to its greenhouse films, eliminating droplets and creating thin layer of running water on one side of its films. Additionally, benefits of collecting more light in the greenhouse, reducing crop growth time, reducing plant disease, and so on, can be achieved with proper use of our plastic films.

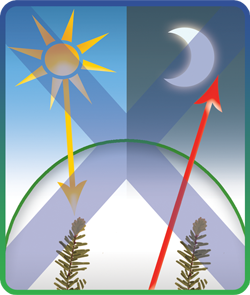

Nocturnal Heat Loss Reduction

Plastic films of Shimi Plastic Yazd prevent lights from escaping the greenhouse by using the IR additive and combining it with the latest world technologies. These films absorb infrared radiation and reduce heat loss during the night. In regions with higher temperatures and more heat, the stored energy in the greenhouse is measured between 10 and 20 percent with regards to a cloudy or clear sky. Research has shown that controlled infrared radiation can increase plant color & density rates, helping boost crop growth. This is due to regulated temperature of the greenhouse at night.

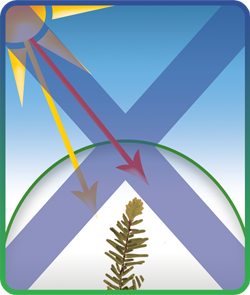

Daytime Heat Reduction

In areas with intense sunlight, blocking part of the infrared radiation from entering the greenhouse, can lower the inside temperature to as low as -10 degrees Celsius. This action ceases to exist in greenhouses in cooler environments and tropical environments. The “cooling effect” is a constant need for shade-loving ornamental plants. Shimi Plastic enhances its films by adding the right color and compounds to its plastic film’s composition, improving it to reflect or absorb infrared radiation that is not used for plant growth. Biggest benefit of using these films is the reduction in cooling costs, in addition to granting workers more comfort, less need for irrigation, reducing plant stress and improving harvest and final product taste.

Durability

Using our special formulation we have decreased the harmful effects of ultraviolet rays and corrosion caused by heat, resulting in an increased lifespan and stability of the films.

The UV-Stabilizers in our greenhouse films increase the durability of our films from one to five seasons depending on the type of films purchased and the geographical location of your farm. Using the highest quality of additives and UV-Stabilizers available in the market has given our films much-increased longevity compared to our competitors in the market, which makes our films have a much higher lifespan than the guaranteed duration.